You stand in the paint aisle. Two options. Zero clarity. Picking the wrong paint can mean peeling, cracking,...

Painting a basement ceiling black sounds bold. But it works. If your basement has exposed pipes, HVAC...

Choosing the right paint for your home often feels like a high-stakes decision. You want a finish that...

Discovering black or green spots creeping across your freshly painted walls can feel overwhelming. You’re...

Fresh paint transforms a room, but the lingering smell can make your space unbearable for days. You open...

Most homeowners think a faded or rusted roof means they need to spend thousands on a full replacement....

Your roof is already brown. Now you need a wall color that makes your whole house look pulled together,...

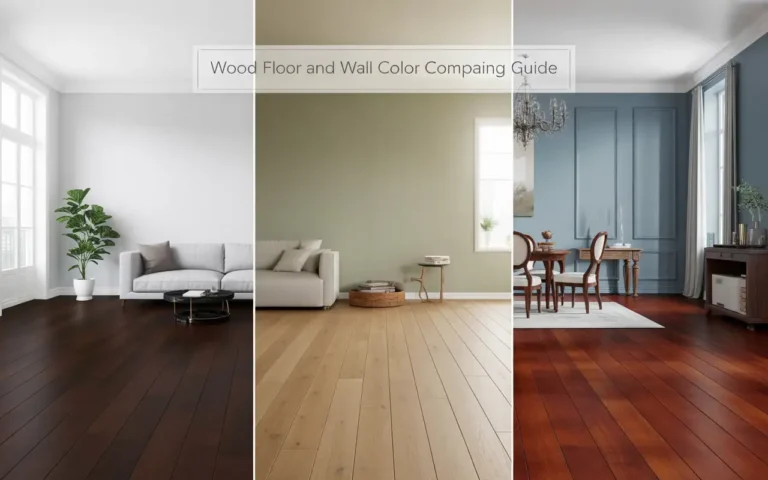

Choosing the right wall color for your wood floors can feel overwhelming. You stand in the paint aisle,...

You spend hours at the paint store. You pick the right shade. The color sample looks great. After you...

Spray paint looks dry fast, but it is easy to ruin a finish by touching it too soon. If you are wondering...

Walk onto any construction site or home renovation project, and you’ll spot them immediately. Painters...

To get the most out of your outdoor space, you need a surface that looks good and stays safe. It is frustrating...

You’ve noticed those hairline cracks spreading across your stucco walls. Water stains keep appearing...

When you look at your outdated oak kitchen, the big question isn’t just about the color. It is about...

Painting aluminum siding is a cost-effective way to revitalize your home’s exterior and boost its...

Changing the look of a room doesn’t always require removing old wallpaper. Many homeowners wonder,...

Painting wainscoting is one of the most effective ways to refresh a room, adding clean lines and a custom-built...

A fresh coat of paint transforms a dull, weathered fence into a beautiful feature that boosts your home’s...

Painting your concrete foundation is one of the fastest ways to boost your home’s curb appeal and add...

Stucco homes have a timeless appeal, but over time, the color fades and the surface can look worn. You’re...

Painting a textured ceiling is a smart way to update your room without the mess and expense of full removal....

Standing in the paint aisle trying to figure out if you need a quart or gallon? You’re not alone....

![How Much Does a Gallon of Paint Cover? [2025 Guide]](https://sdcustompainting.com/wp-content/uploads/2025/11/how-much-does-a-gallon-of-paint-cover-image.webp.webp)

For a standard, smooth, and primed interior wall, a gallon of paint covers approximately 350 to 400 square...

Choosing paint colors for your home can feel overwhelming. You want each room to look its best without...

Dated, dull Formica laminate can drag down the look of an entire kitchen. The great news is you do not...

Wall repairs are part of property ownership. Whether you’re mending nail holes before moving out or patching...

Thinking about giving your home’s exterior a fresh look? Clapboard siding has been a trusted choice...

Choosing the right paint color for your home’s exterior is a big decision, especially when working...

Finishing a paint job feels great until you look at those messy rollers. Most people either toss them...

Planning a home improvement project means choosing the right finish for your surfaces. The choice between...

Painting your home’s exterior is the fastest way to boost curb appeal and protect your investment. When...

Tired of looking at outdated kitchen cabinets but don’t want to spend thousands on a full replacement?...

Removing old kitchen cabinets is often the first step of a major kitchen remodeling. While this task...

Have you just finished painting a room only to notice ugly streaks ruining your hard work? Those visible...

Most people who own a home agree that painting trim is the most annoying part of any room makeover. You...

Do you have beautiful wooden cabinets, trim, or furniture that is hidden by a dark, shiny, and clearly...

Home /

Crown molding transforms ordinary rooms into spaces with visual appeal and character. This...

Home /

Picking the right shade of blue paint for the outside of your house can quickly improve its...

Most people never look up when designing a room. But your ceiling holds massive potential to transform...

You just finished painting your bedroom. The walls look amazing. But now you’re wondering if it’s...

Home /

Painting stripes transforms any room from plain to stunning in just one weekend. Vertical stripes...

Painting an accent wall is an easy and cost-effective way to transform any room. Whether you want to...

Proper room preparation makes all the difference between a paint job that lasts years and one that peels...

Home /

Painting trim transforms any room from ordinary to stunning. Fresh paint on baseboards, door...

Home /

A brick fireplace can transform your living space from outdated to stunning with the right...

Painting a ceiling can feel overwhelming. Most people avoid it because they worry about drips, roller...

Choosing between stain and paint for your next wood project can feel confusing. You want your deck, fence,...

Paintable caulk is an acrylic-based or hybrid sealant specifically engineered to fill joints, cracks,...

Home /

How Long Does Interior Paint Last? The average lifespan of most interior paints lies somewhere...

Your kitchen cabinets look tired and outdated, but the quote from a contractor to replace them just made...

With over 2,700 paint colors available from major manufacturers and 6 different sheen levels, choosing...

Today, we are seeing choices in natural wall surfaces besides painted drywall and wood. While there is...

Planning a home painting project can feel overwhelming, especially when you’re unsure about costs....

Home

Over 24 million homes in the US contain lead-based paint hazards that pose serious health risks....

Planning an exterior paint job means more than picking colors and buying supplies. The weather plays...

Your vinyl siding looked great when it was new. But after years of sun, rain, and weather, the color...

You have a wood surface with an old polyurethane finish, and you want to paint it. The first question...

Kitchen renovations can run $20,000 to $50,000, but painting melamine cabinets provides the same aesthetic...

Paint is not cheap, and no one wants to throw away half a can that might still work. Many people ask...

Home /

How to Remove Mold from Painted Walls (Easy DIY Guide)

Planning a fresh look for your home?...

The Best Type of Paint for Kitchen That Lasts 10+ Years

Choosing the right type of paint for kitchen...

Home /

How to Remove Mold from Painted Walls (Easy DIY Guide)

Wondering how to paint over oil based...

Can Interior Paint Be Used Outside? Expert Guide 2025

You just finished painting a room and have leftover...

Can You Paint Over Mold? Why Experts Say Never

Can you paint over mold? The answer is a definitive no...

Home /

How to Remove Paint from Metal: 6 Pro Methods (2025)

Removing old or failing paint is necessary...

Cabinet Refinishing vs Painting: ROI Comparison 2025

Staring at outdated kitchen cabinets wondering if...

How to Clean Painted Walls (Without Damage) – 2025 Guide

Studies show that dirty walls can reduce...

Home /

Acrylic vs Latex Paint for Homes: Which is Better?

Choosing the right paint is about matching...

Home /

How to Remove Mold from Painted Walls (Easy DIY Guide)

You want your home to look its best....

Transform Your Home With Kitchen Remodeling Services in San Diego, CA—Why It’s Worth the Investment

A...

How Can Commercial Exterior Painting Services Boost Your San Diego Property’s Value?

A fresh coat...

No posts found

At SDCP we celebrate the beauty of painting from bold brushstrokes to delicate details. Explore, get inspired, and share your passion for art with us.

Quick Links

Contact Us

Copyright © 2026. All Rights Reserved San Diego Custom Painting. Powered by LocalPro1.